OpenAg Wiki Archive

Archived Contents from the original OpenAg Wiki (snapshot on Apr 8, 2020)

The archived wiki only includes information up the v3.0 version of the PFC-EDU, and is here for preservation purposes. You can find resources about the latest version of the PFC v4.0 on the Personal Food Computer resources page.

Personal Food Computer 3.0 (PFC_EDU)

The OpenAg™ Personal Food Computer 3.0 (PFC_EDU) is the latest evolution of the Personal Food Computer.

The PFC 3.0 (PFC_EDU)The PFC_EDU was designed by the OpenAg Project, in collaboration with the OpenAg community, especially educators working in both informal and formal education settings (e.g. libraries, schools, museums). It can be built, used, modified and hacked by the community for any number of applications.

Like any Food Computer™, the PFC_EDU is a controlled environment agriculture technology platform that uses robotic systems to control and monitor climate, energy, and plant growth inside its specialized growing chamber. The PFC_EDU design has been scaled down from previous versions of the PFC in cost, size and complexity, and offers a spectrum of control so that users can make their growing experience as manual or as automated as they would like.

Design decisions for the PFC_EDU were based on cost, ease of manufacture, improved data validity, testing in schools, libraries, and museums, as well as feedback from the community. We involved an PFC_EDU Advisory Board comprised of folks from across the US, with a range of backgrounds and experience using novel STEM technology tools, to help us understand what design features were most engaging and useful for educators working with nerdfarmers between 8 and 14 years old.

But the PFC_EDU isn’t just for educators! Their insights and recommendations helped design a small, engaging, modular Food Computer that nerdfarmers with a broad spectrum of skills, resources, and interests can build and use, for a wide variety of scientifically rigorous, citizen-science experimentation.

New Shape

Its “3U” form factor (30cm3 / 12in3) is comparable to NASA’s Veggie Production System, and compatible with the Growing Beyond Earth Challenge STEM Education Program.

New Brain & Central Nervous System

Internally it runs our embedded software (the OpenAg Brain) on a robust Beaglebone black wireless (BBB) and the custom Central Nervous System (CNS) circuit board reads sensor data and controls LEDs to create, edit or maintain the Climate Recipe running inside. Nerdfarmers have the option of adding more advanced sensors and peripherals (pH, EC, DO, water temperature, and a USB camera) to the baseline CNS, as their skill level and resources allow.

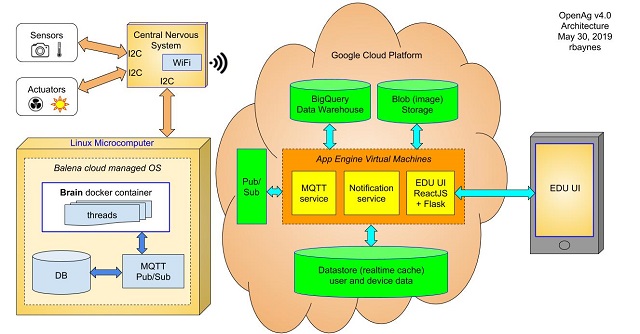

New Interfaces & Cloud Backend

There are a new set of cloud services (the OpenAg Cloud) that support the backend of the PFC_EDU, and connect it to the Open Phenome (archive.org link) (OpenAg’s open source, digital library of Food Computer data and Climate Recipes).

The PFC_EDU also has a new web-based, front-end interface as well as a new device UI, for advanced networking, remote troubleshooting and monitoring. As of Fall 2018, both are still in development and testing with libraries and schools in a pilot test in the Boston area. You can get a sneak peak at both by taking a look at the Configuration Guide, below.

Get Started

Watch the Welcome Video and see the documentation below for more details.

Videos & Support Materials

- Welcome to the PFC_EDU (youtube video)

- Final Assembly Guide (created with i2 Learning for Fall 2018 Pilot Test)

- Configuration Guide (created with i2 Learning for Fall 2018 Pilot Test)

- “Get Growing” Germination Guide

PFC_EDU Bill of Materials and Design

The files you’ll need to build a PFC_EDU from scratch are below:

- PFC 3.0 (PFC_EDU) Specifications Sheet

- PFC_EDU Assembly Bill of Materials (total unit BOM, Google spreadsheet) (archive.org link)

A baseline PFC 3.0 can be assembled for about $500 with the raw materials below. For folks who want to outsource more advanced components to professional manufacturers, see “Getting parts of a PFC_EDU manufactured” below.

- Main chassis (frame cut by CNC)

- Water reservoir (laser cut or vacuum-formed)

- Air stone and hose

- A completed “Central Nervous System” (CNS), which includes a printed circuit board (PCB) and

- BeagleBone Black

- LED lights

- Fans

- Temperature, humidity and C02 sensors

- Air pump

- USB camera

- Power supply and cord

- For more advanced environmental data, the PFC_EDU CNS can be modified to include these optional sensors:

- EC probe (a conductivity sensor for nutrient concentration)

- pH probe

- Water temperature probe

Software

All the details for getting your BeagleBone Black ready, software installed, configured and updated are available in the ReadMe’s at the links below.

- OpenAg Brain (Django/Python)

- OpenAg Cloud (Python/React/Flask)

Note the 'OpenAg Cloud' now points to a self hosted docker based option

OpenAg Cloud Architecture Description

NOTE: The Architecture described above was the original Google Cloud Platform based backend. The new 'self_hosted_backend'

will have a description in it's repository's readme

Hardware

Electrical

Files for circuit board, sensors, and actuators (“central nervous system”)

- Circuit Board Design files & Assembly Bill of Materials

- Optional Sensors Bill of Materials* (Google Spreadsheet) (MISSING DATA)

note: CO2 and environmental temperature/humidity sensors are included in the baseline CNS BOM. The pH, EC, water temperature and camera are optional and included in the Optional Sensors BOM.

Mechanical/Frame

Files for the chassis

- Chassis design files and Bill of Materials (

NOTE: the original google sheets BOM with links is missing) - Chassis Manufacturing Key (chassis parts’ cutting specifications, parts data, and file locations) (

NOTE: the orignal google sheet version is missing)

Additional Hardware

- Small components (MISSING DATA) you’ll need (air pump, air stone, USB camera)

Getting PFC_EDU Parts Manufactured

This list of manufacturers is meant to help OpenAg community members of all skill levels build a PFC_EDU. Add vendors you’d suggest to the community list of manufacturers here (MISSING DATA).

You can build one on your own, or seek out your local FabLab, Makerspace, or contractors like those below (or in the community list (MISSING DATA)) to help you get a chassis cut, a circuit board printed, or LED light panel created.

- File(s) needed to get the chassis made.

- File(s) needed to get the reservoir made.

- Files needed to get the baseline CNS made, which includes circuit board, lights, fans, temp/humidity/CO2 sensors, & power supply. Does not include optional sensors.

Mechanical Contract Manufacturers

Electronic Assembly Houses

Other Sources

Community’s Manufacturer List (MISSING DATA)

Note: Vendors listed here are simply suggestions of some manufacturers that may be helpful to the OpenAg community. Listing a vendor here doesn’t suggest or imply the endorsement of these organizations, their products, or their services by the OpenAg community. As always, check your sources!

Licensing

- License: GPL 3.0.

- Documentation license: CC-BY-SA